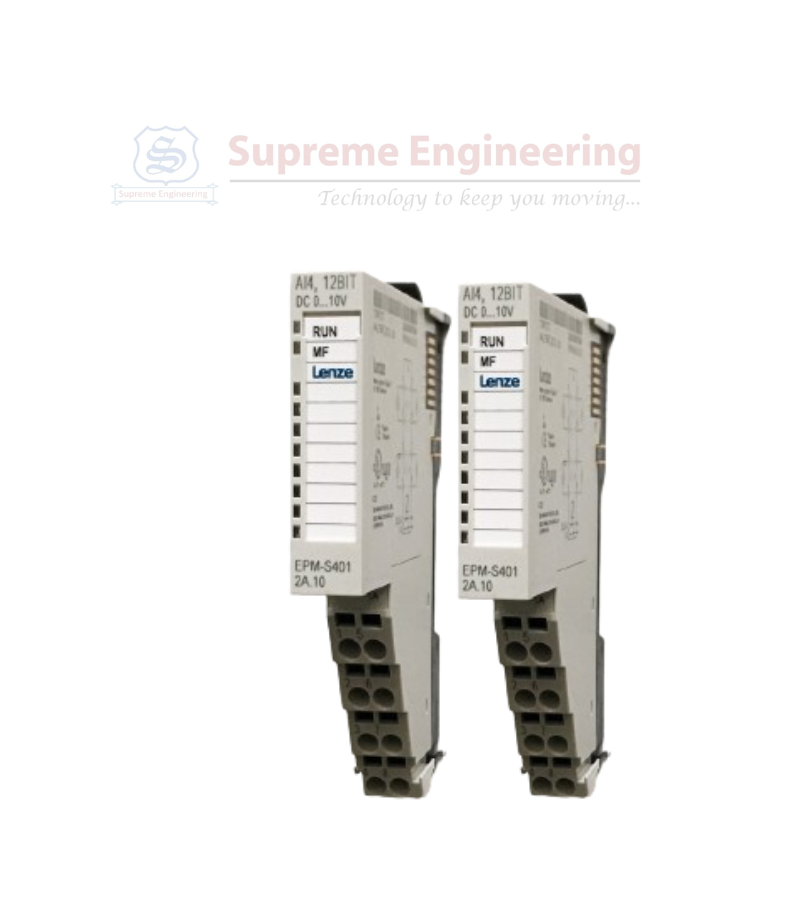

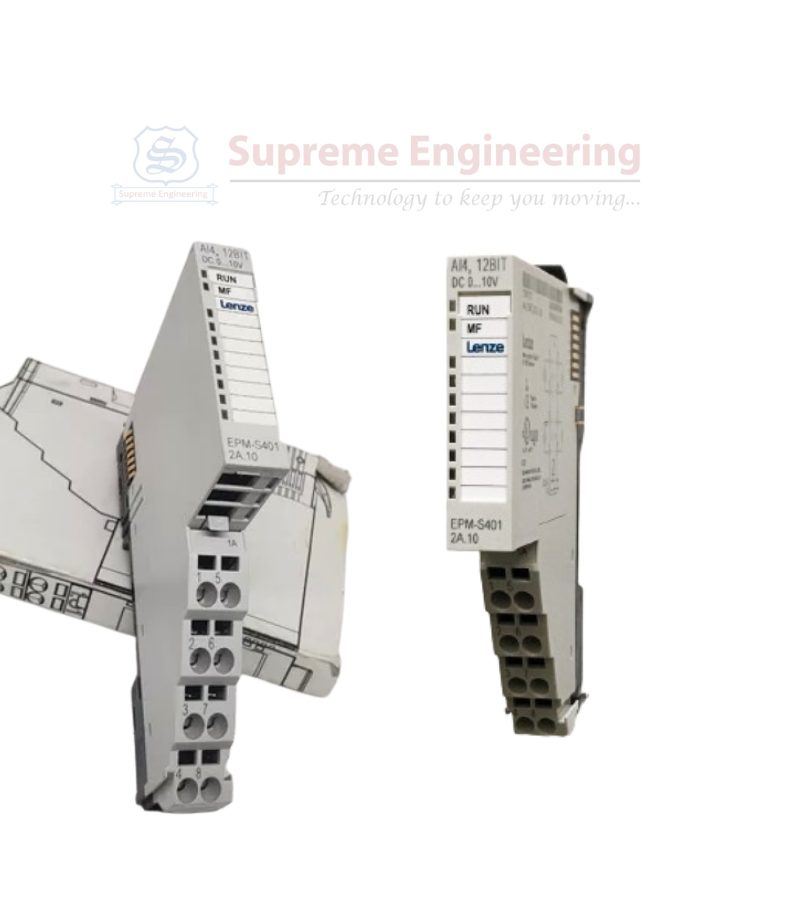

Lenze EPM S401.2A

The Lenze EPM S401.2A is a programmable logic controller (PLC) designed for industrial automation. Known for its reliability and performance, this device is ideal for controlling and managing complex machinery in various industries. Its advanced features and robust design ensure smooth operation and adaptability to different automation tasks.

Features

- Compact Design: Space-saving module, ideal for integration into existing control systems.

- Flexible Programming: Compatible with Lenze’s programming software for customized automation solutions.

- High Reliability: Ensures continuous operation in demanding environments.

- Diagnostics: Built-in diagnostic tools for quick fault detection and troubleshooting.

- Energy Efficiency: Optimized for low power consumption.

- Scalability: Modular architecture supports system expansion as required.

- Memory:

- Non-volatile memory for program storage

- Capable of handling extensive control programs

- Input/Output (I/O):

- Multiple digital and analog channels

- Supports standard industrial I/O configurations

- Communication Interfaces:

- Ethernet for network integration

- CANopen for device communication

- Operating Environment:

- Temperature range: 0°C to 50°C

- Designed for harsh industrial conditions

- Ease of Use: Simple installation and configuration process.

How It Works

- Input Processing: Receives signals from connected sensors, switches, and other input devices.

- Logic Execution: Processes the inputs based on user-defined programs and determines the required output actions.

- Output Control: Sends commands to actuators, motors, or other output devices to execute the desired operations.

- Communication: Facilitates data exchange with other devices and systems through Ethernet and CANopen interfaces.

- Monitoring and Maintenance: Continuously monitors system performance and provides alerts for maintenance needs.

The Lenze EPM S401.2A offers a dependable solution for industrial automation, combining flexibility, efficiency, and advanced control capabilities to meet the needs of modern manufacturing and production processes.

Reviews

There are no reviews yet.