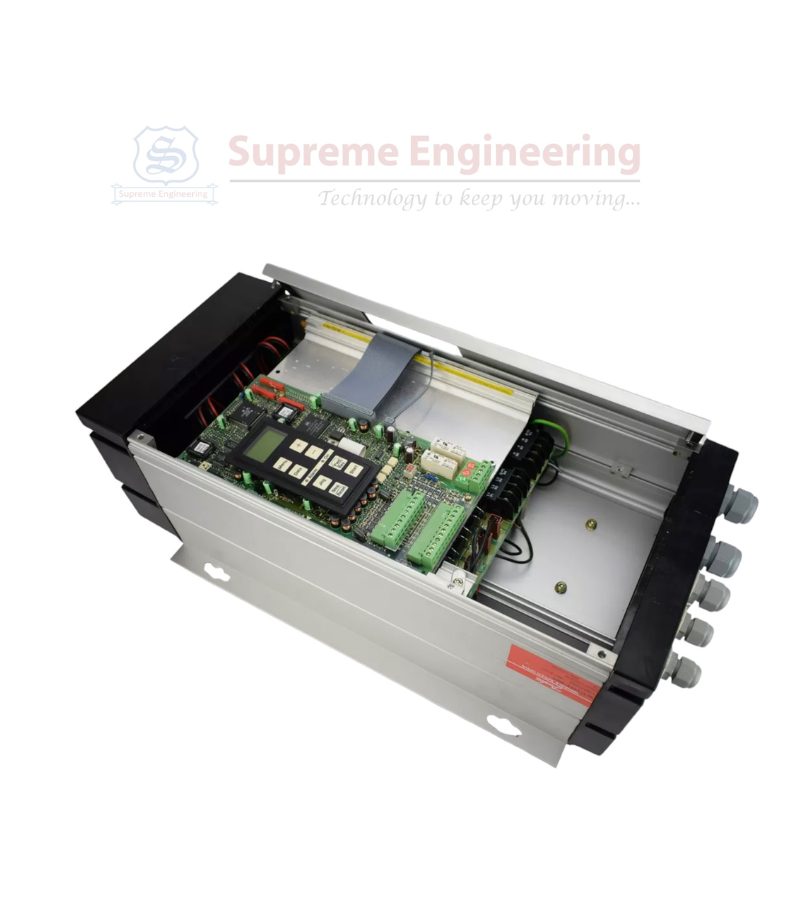

The Danfoss VLT 3000 is a variable frequency drive (VFD) designed for controlling the speed and torque of AC motors. It was widely used in industrial applications, such as pumps, fans, conveyors, and machine tools, to improve energy efficiency and process control. Although the VLT® 3000 series is now discontinued and replaced by newer models (such as the VLT® AutomationDrive FC 300), it is still found in many existing installations.

How It Works

The Danfoss VLT 3000 operates by converting incoming AC power into DC power and then back into adjustable-frequency AC power using pulse-width modulation (PWM). This allows precise control over motor speed and torque, reducing energy consumption and mechanical wear.

Basic Working Principle:

- AC to DC Conversion: The drive rectifies the incoming AC voltage to DC.

- DC Link: A capacitor bank smooths out the DC voltage.

- DC to AC Inversion: The drive’s IGBT-based inverter converts the DC back into AC with variable frequency and voltage, which controls motor speed.

- Control System: The drive monitors parameters (such as load, speed, and torque) and adjusts output accordingly.

- Since the VLT 3000 series includes multiple models, the exact specifications may vary, but typical specifications include:

Key Features:

✔ Energy Savings: Optimized for applications that require variable speed control.

✔ Soft Start/Stop: Reduces mechanical stress on motors and equipment.

✔ Motor Protection: Built-in thermal protection and fault detection.

✔ User-Friendly Interface: Digital display with programming options.

✔ Fieldbus Connectivity: Supports Modbus for integration into automation systems.

✔ Customizable Parameters: Speed, acceleration, deceleration, and torque control.

Applications of Danfoss VLT 3000

- Pumps: Water supply, wastewater treatment, and irrigation systems.

- Fans & Blowers: HVAC systems, cooling towers, and industrial ventilation.

- Conveyors: Material handling in manufacturing and logistics.

- Mixers & Agitators: Used in food processing, pharmaceuticals, and chemicals.

- Machine Tools: CNC machines and production equipment.

Replacement & Upgrades

Since the Danfoss VLT 3000 is discontinued, Danfoss recommends upgrading to the VLT® AutomationDrive FC 302, which offers:

✔ Advanced motor control (including sensorless vector control).

✔ Improved energy efficiency and adaptive programming.

✔ More robust communication options (PROFIBUS, Ethernet/IP, etc.).

✔ Better protection against voltage fluctuations and overloads.

Would you like recommendations for a replacement drive based on your industry needs? 🚀

Reviews

There are no reviews yet.