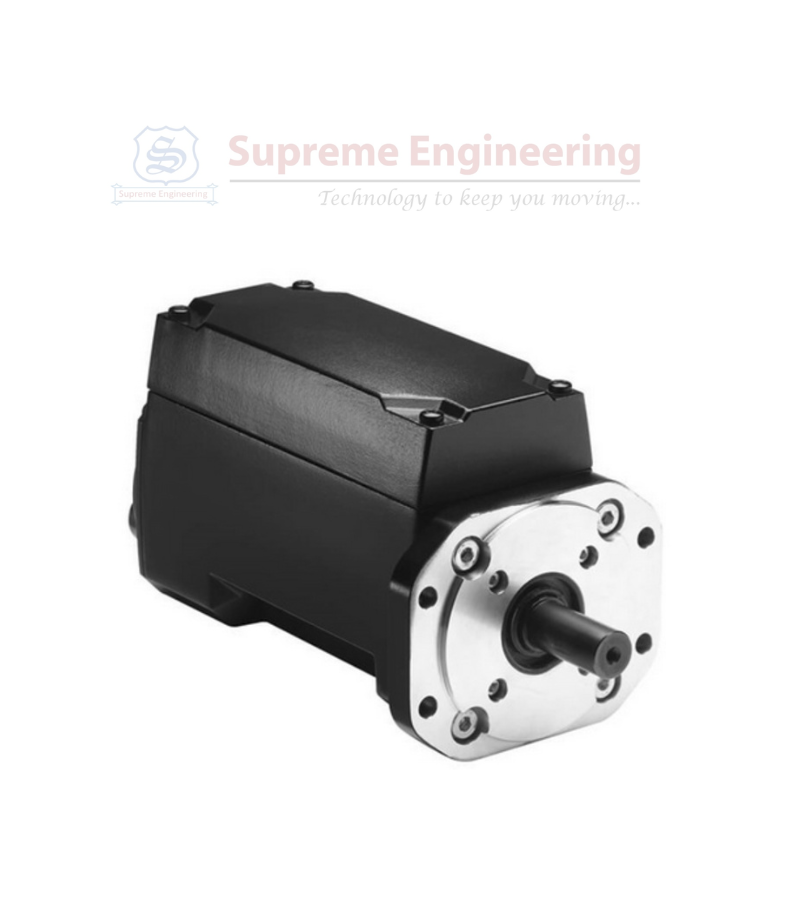

Danfoss VLT® Integrated Servo Drive ISD® 410

The VLT® Integrated Servo Drive ISD® 410 is a decentralized servo drive designed for motion control applications in industrial automation. It integrates a servo motor, drive, and controller into a single compact unit, eliminating the need for centralized control cabinets.

How to Use the ISD® 410

1. Installation & Wiring

- Connect the ISD 410 directly to the machine structure.

- Use Danfoss Power and Communication Cables to daisy-chain multiple units.

- Ensure proper cooling and protection based on environmental conditions.

2. Configuration & Programming

- Use VLT® Motion Control Tool MCT 10 software for parameter setup and diagnostics.

- Set speed, position, and torque control via Ethernet, EtherCAT, or PROFINET communication.

- Integrate with PLC systems for seamless automation.

3. Operation & Maintenance

- Monitor real-time performance using Danfoss diagnostic tools.

- Perform firmware updates and fine-tune settings as needed.

Advantages of ISD® 410

✅ Decentralized Design – Reduces the need for large control cabinets and simplifies wiring.

✅ Flexible Scalability – Multiple drives can be connected in a daisy-chain, allowing modular expansion.

✅ High Energy Efficiency – Reduces power consumption by using regenerative braking and optimized motion control.

✅ Faster Installation & Maintenance – Fewer cables and compact design make setup and servicing easier.

✅ Robust Industrial Communication – Supports EtherCAT, PROFINET, and other fieldbus protocols for seamless integration.

✅ Precision Control – Delivers high-performance servo control for demanding automation applications.

Would you like recommendations on where to buy or how to integrate VLT® Integrated Servo Drive with your existing systems? 🚀

Integrated Safety: Safe Torque Off (STO)

- I/O Ports:

- Digital and Analog Inputs/Outputs

- Encoder Inputs

3. Mechanical & Environmental Features:

- Motor Type Compatibility: Synchronous servo motors

- Protection Class: IP67 (dustproof and water-resistant)

- Operating Temperature: -10°C to 40°C

- Cooling Method: Passive or forced cooling

4. Features & Performance:

- Daisy-Chain Connectivity: Allows up to 64 drives in a single system

- Energy Efficiency: Uses regenerative braking for lower power consumption

- Compact Design: Eliminates the need for control cabinets

Would you like help selecting a model that fits your industrial needs? 🚀

Direct Chat With Us

Reviews

There are no reviews yet.