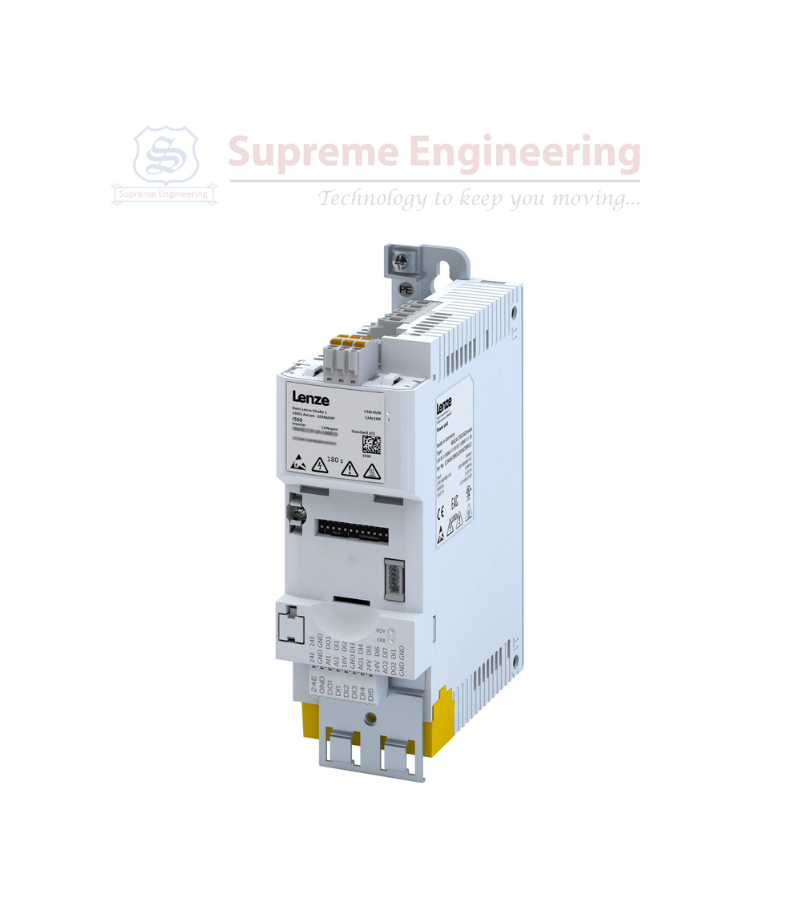

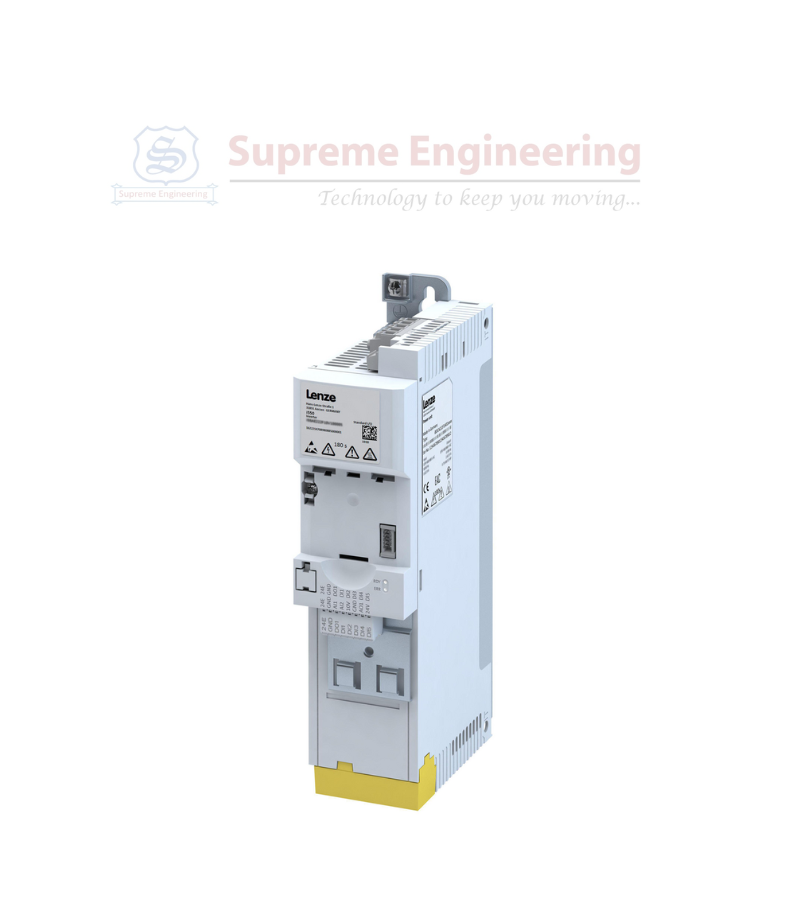

Lenze i550 Frequency Inverter

The Lenze i550 frequency inverter is a compact designed for industrial automation and motor control applications. It offers flexibility, scalability, and user-friendly integration, making it suitable for a wide range of industries, including manufacturing, material handling, and process automation.

Features

- Compact Form Factor: Space-saving design for seamless integration into control cabinets.

- High Efficiency: Optimized for energy-saving operation, especially in variable speed applications.

- Integrated Safety Features: Supports STO (Safe Torque Off) for enhanced safety compliance.

- User-Friendly Configuration: Intuitive setup via keypad or Lenze EASY Starter software.

- Scalable Connectivity: Multiple communication options for flexible integration with automation networks.

- Versatile Applications: Ideal for pumps, fans, conveyors, and other motor-driven systems.

- Diagnostic Tools: Real-time monitoring and troubleshooting via software interfaces.

- Control Methods:

- V/F (Volts/Hertz)

- Sensorless Vector Control

- Closed-Loop Vector Control

- Interfaces:

- Ethernet, CANopen, Modbus

- Optional communication modules for PROFINET, EtherCAT, and more

- Dimensions: Compact design with modular structure for easy installation

- Cooling System: Integrated air cooling for efficient thermal management

- I/O Ports:

- Digital inputs and outputs

- Analog inputs

- Relay outputs

How It Works

- Input Power: Converts incoming AC power to DC through a rectifier and then back to controlled AC for motor operation.

- Control Algorithms: Uses advanced control methods (V/F, vector control) to regulate motor speed and torque with precision.

- Output Delivery: Sends customized voltage and frequency signals to the motor based on the desired operational parameters.

- Communication: Interfaces with automation systems via standard or optional communication protocols for centralized control.

- Safety and Monitoring: Implements STO to prevent unintended motor operation and offers diagnostics for performance optimization.

- Energy Efficiency: Adjusts motor operation to match load requirements, reducing energy consumption and operational costs.

The Lenze i550 Frequency Inverter delivers reliable motor control with modularity, scalability, and energy efficiency, making it a top choice for modern industrial automation systems.

Reviews

There are no reviews yet.